Transformer fires are a cause of concern and liability for electric utilities. An explosion usually takes place before fire. This results in loss of life and damage to the neighboringequipment’s apart from causing power outage.

Fire protection for power transformers has undergone a manor transformation from conventional emulsifier for quenching the fire. Present day technology uses unique feature of depressurizing the transformer tank thereby preventing an explosion and fire. Not only is the transformer saved but can be put back into service within a short time.

The Indian Electricity Rule stipulates provision of Nitrogen fire Protection System as alternate to IS 3034 system.

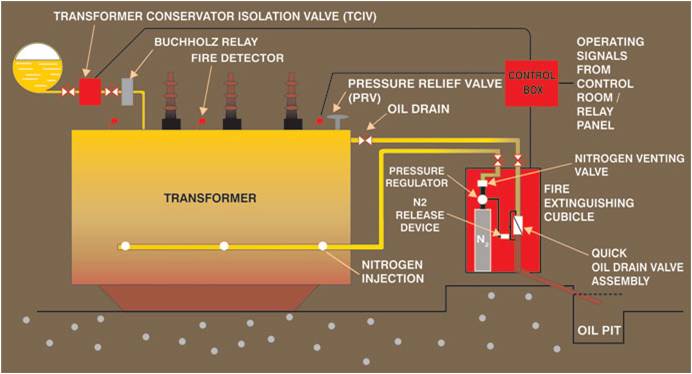

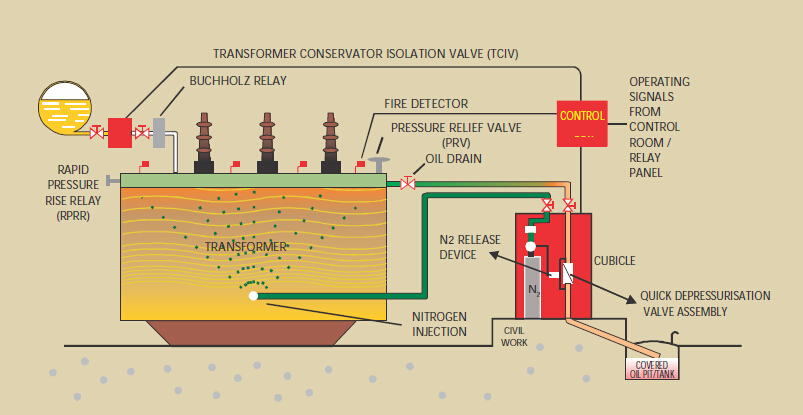

The pressure buildup within the transformer under fault conditions is diagnosed with the help of combination of signals from Differential relay, Buchhotlz oil surge relay or Rapid Pressure Rise Relay or Pressure Relief valve alongwith transformer isolation signal where upon a system activation signal is generated.

The system can be fitted on a new transformers as also retrofitted on an old transformers without modifications. The system can be operated in auto, remote electrical mode or manual mode thus ensuring reliability in the event of power failure.

PRINCIPAL OF OPERATION :

The system is simple in operation. There are two Automatic modes of operation namely Prevention mode and Extinguishing mode, apart from Remote electrical and Local Manual mode in case of power failure.

Advantage :

Regulated gas release device The above method being simple and fail safe is used the world over on many transformers for protecting them from explosion and consequent fire.