Paint booths pose a high fire risk because of work done inside with flammable and combustible materials, which leads to fast-spreading and high-toxicity fires. The most common place where we can find these facilities is in body and paint shops, where they tend to be prefabricated modular cabins easily assembled onsite.

The accumulation of airborne vapors and paint dust creates an extra risk due to the danger of explosions. The high temperature generated internally during drying processes also increases the risk of ignition.

Since they are considered high-risk enclosures, booths must meet certain safety requirements to prevent accidental fires. The focus is on reducing ignition and explosion risk factors such as the booth controller, the ventilation system, etc.But the primary focus is deploying a firefighting system that acts quickly and effectively to minimize damage.

The Booths Must :

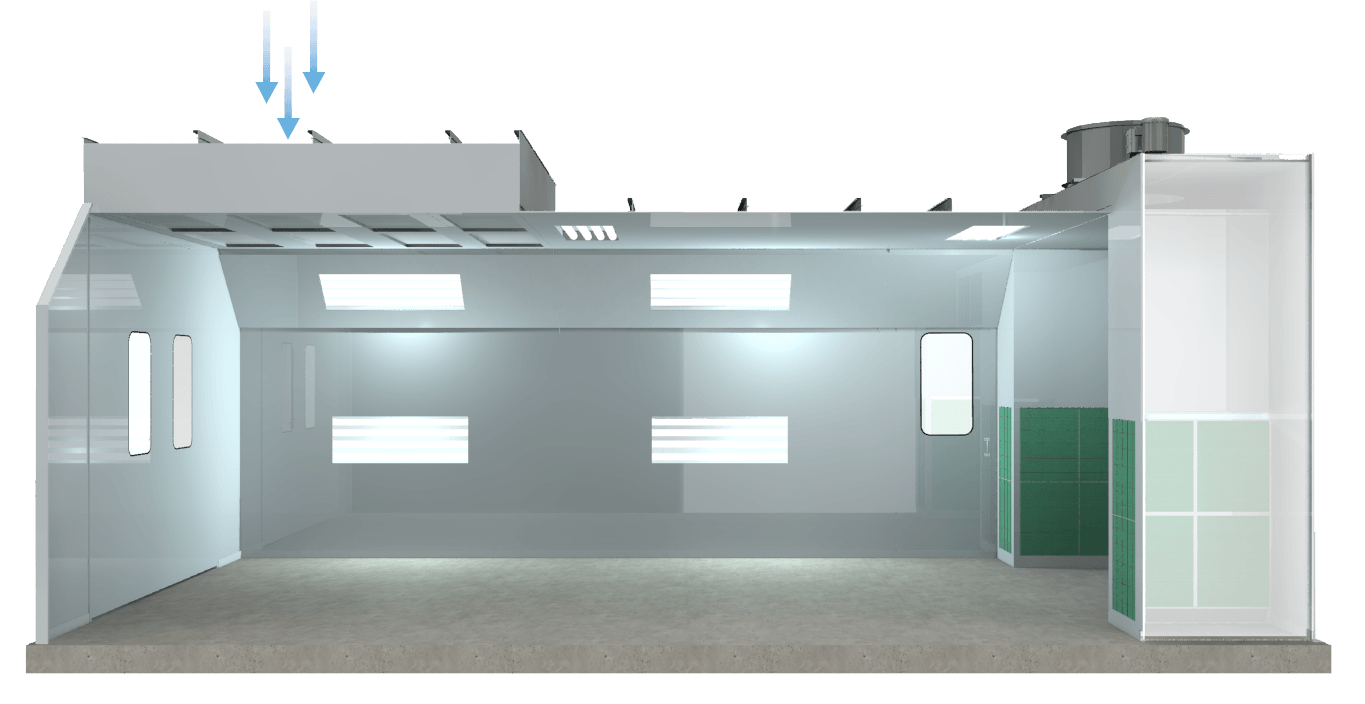

These enclosures are prepared for painting, coating and drying the parts to be treated. They must have

The interior of a paint booth must be protected by an automatic extinguishing system to control any incident caused by leaks, spills or the accumulation of vapour from flammable and combustible liquids.

Triggering of the automatic fire extinguishing system must stop the ventilation system and activate the closure of fire doors to maintain the concentration of gas or chemical powder applied inside the premises for extinguishing purposes. The extinguishing equipment must protect the environment, the plenum and the exhaust duct through nozzles properly located to cover all paint booth risk areas.

Agents recommended by SVS for this type of applications, given the hazard characteristics, are as follows

SVS CO2 is composed of highpressure cylinders, in a bank, depending on the amount of gas needed. Each application is studied individually prior to designing an installation. The high CO2 pressure allows using long pipe runs in large installations and being able to separate cylinders from the protected hazard to avoid damage in the event of explosions.

SVS Water Mist systems adapt to the characteristics of each cabin. Depending on its size, placement on or off the Nozzles, as well as the amount of water required by each nozzle for a minimum of 30 minutes discharge. Both options are available modular systems with capacities of up to 500 ltrs or tanks with capacities up to 2000 ltrof water pressurized by a Nitrogen Cylinder bank or stand alone Pumps both total flooding and local application. It is a suitable system for the comprehensive protection of booths, plenums and filters.